Technical Development

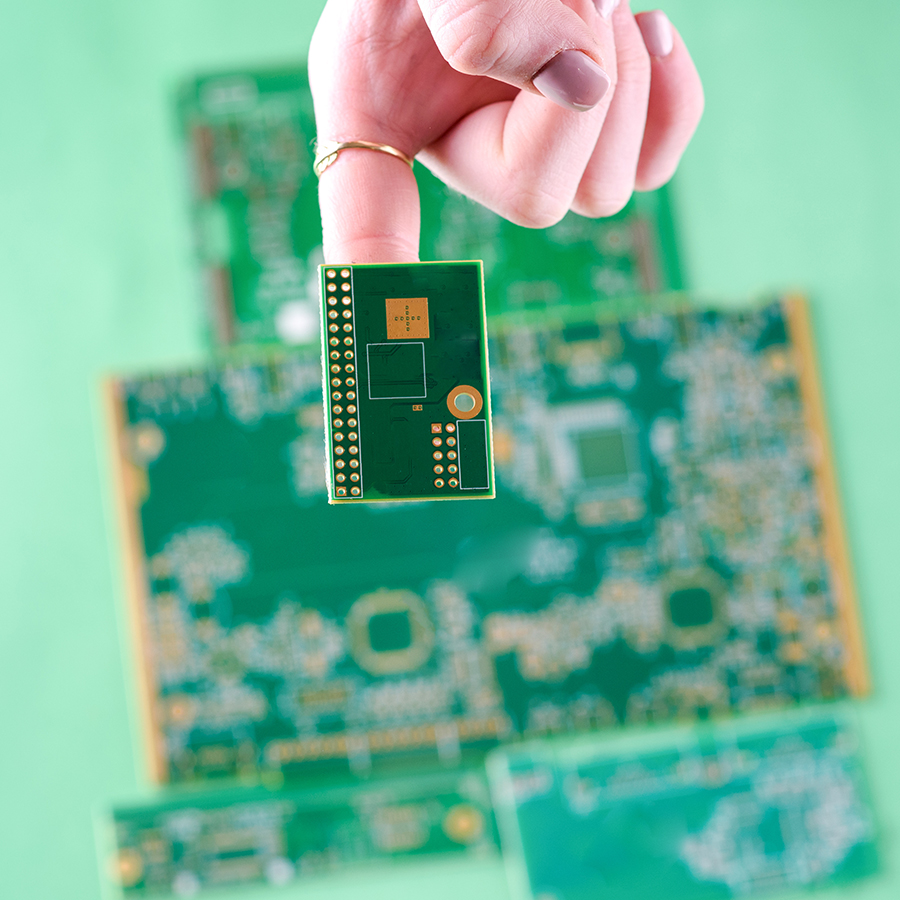

Rigid PCB

Transparency X , Flexibility X

Flexible PCB

(none-transparency)

Transparency X , Flexibility O

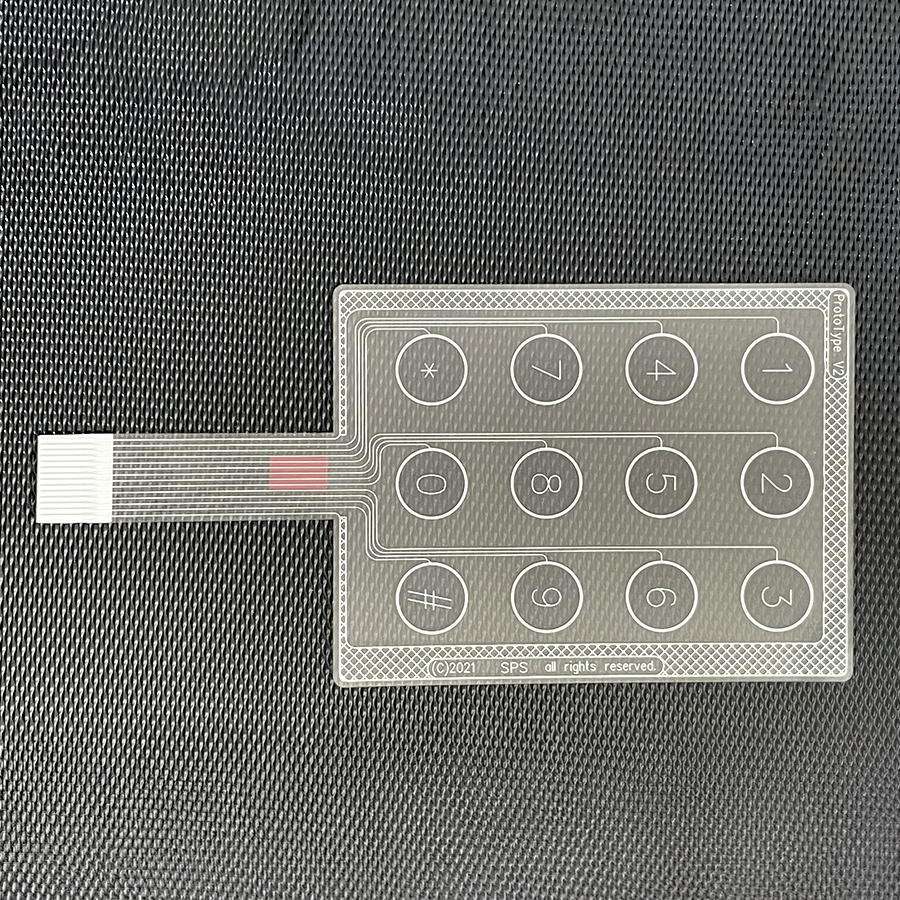

Transparency

Flexible PCB

Transparency O , Flexibility O

Quality satisfaction with improved durability

Compare silver ink product

ICompared to ITO/Silver + FPCB combination product, Cost reduction of more than 50%

Using capacitive touch IC and MCU, simple touches and wheel/slide operations are available.